Injection mold production

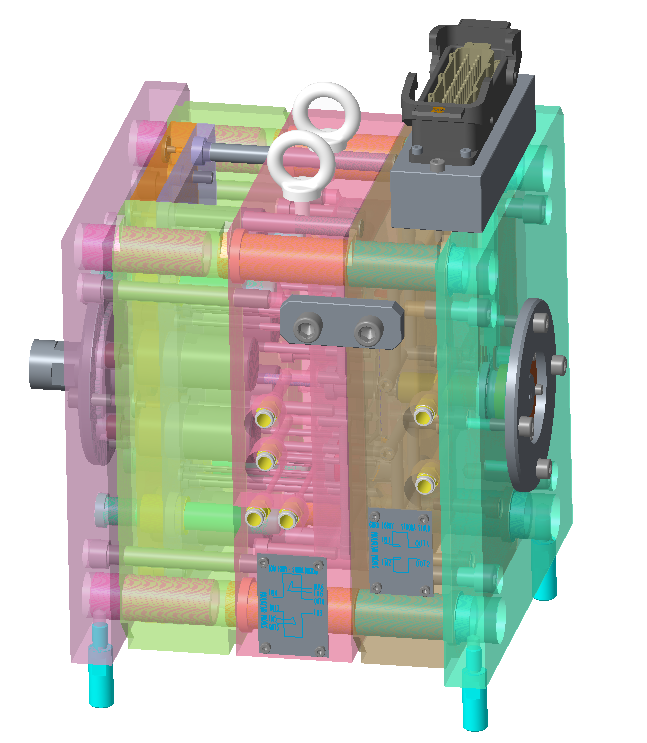

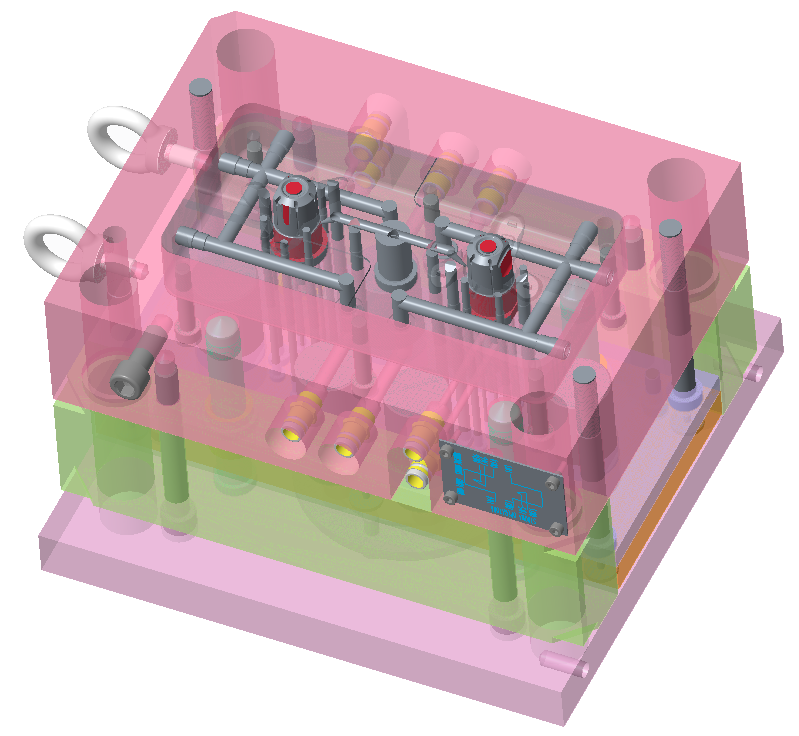

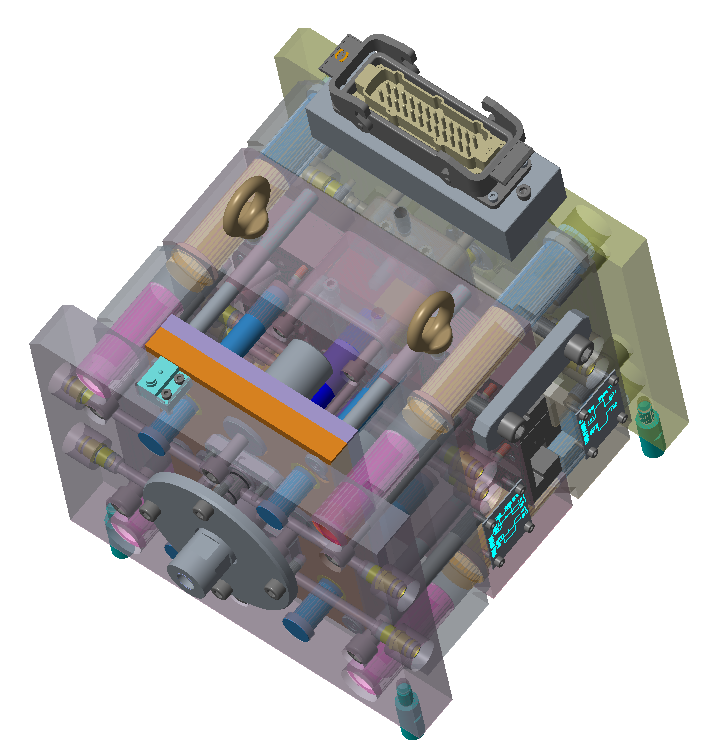

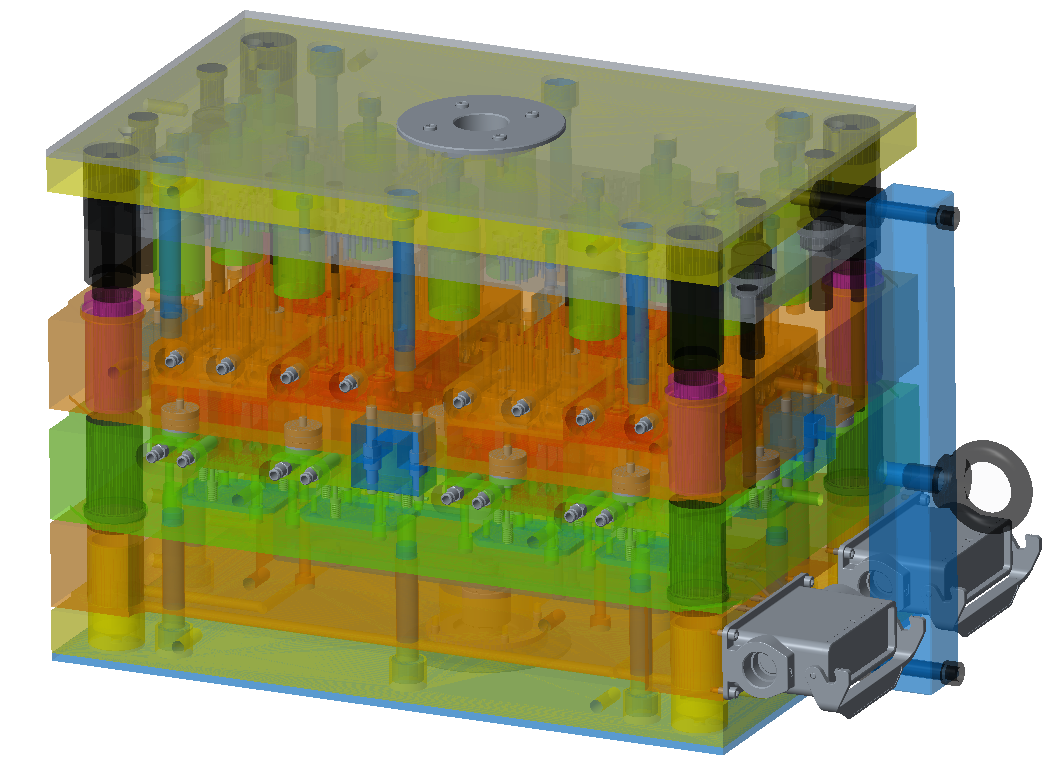

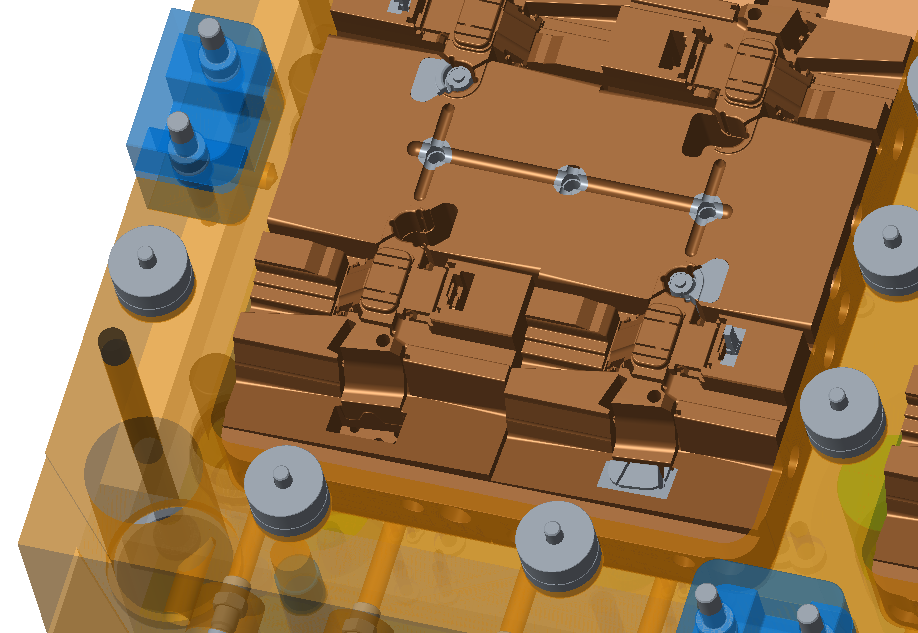

Our work in the construction of production injection molds is based on the most modern technologies and enables us to carry out and implement complex projects.

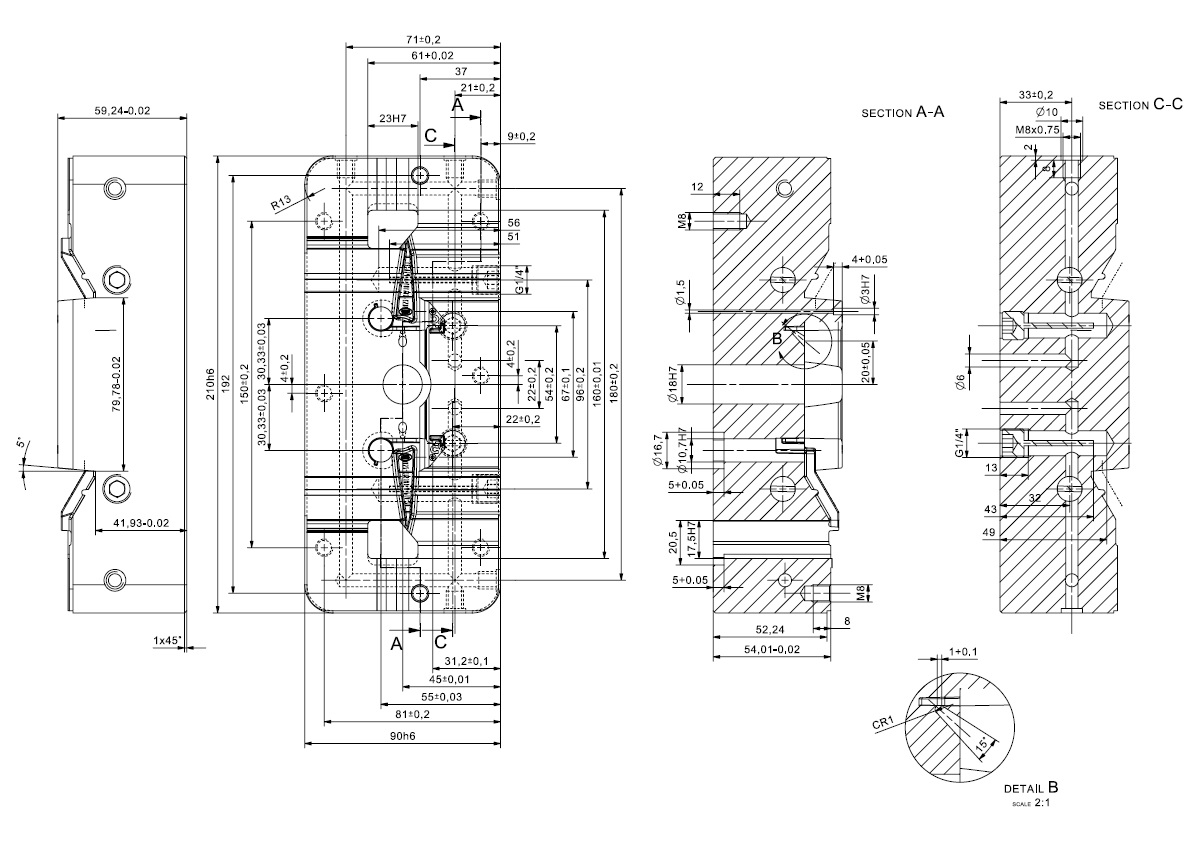

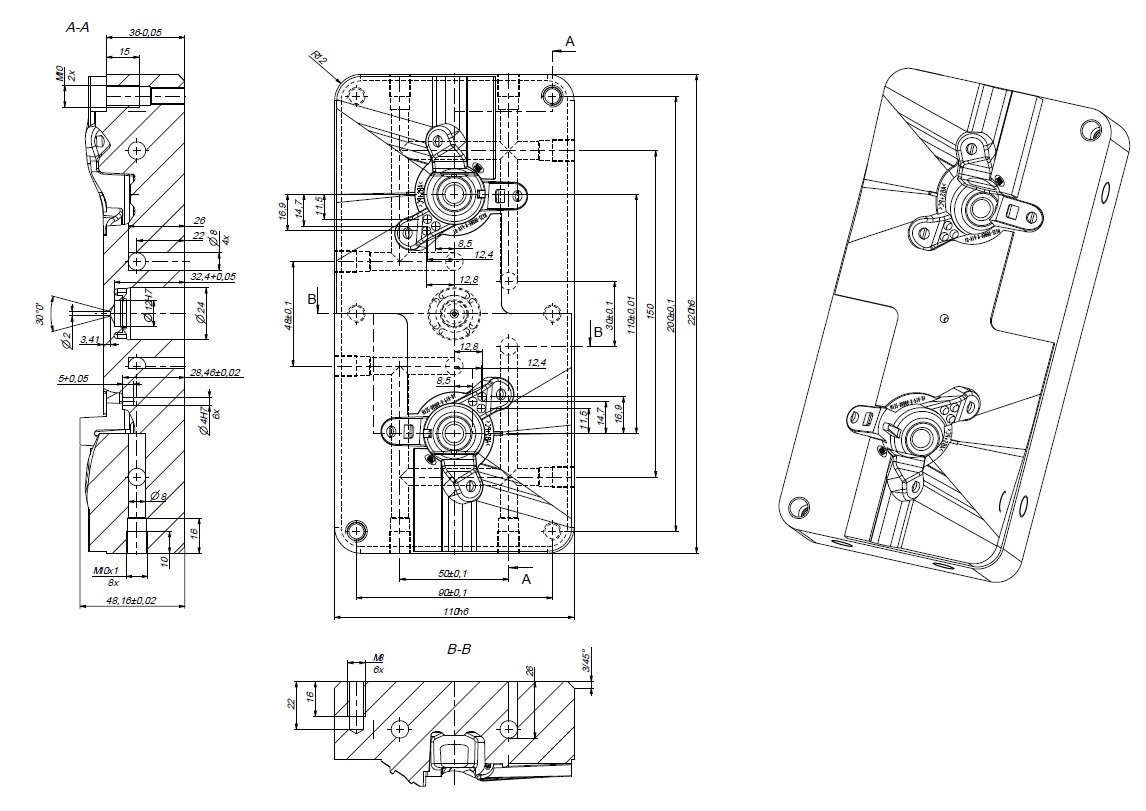

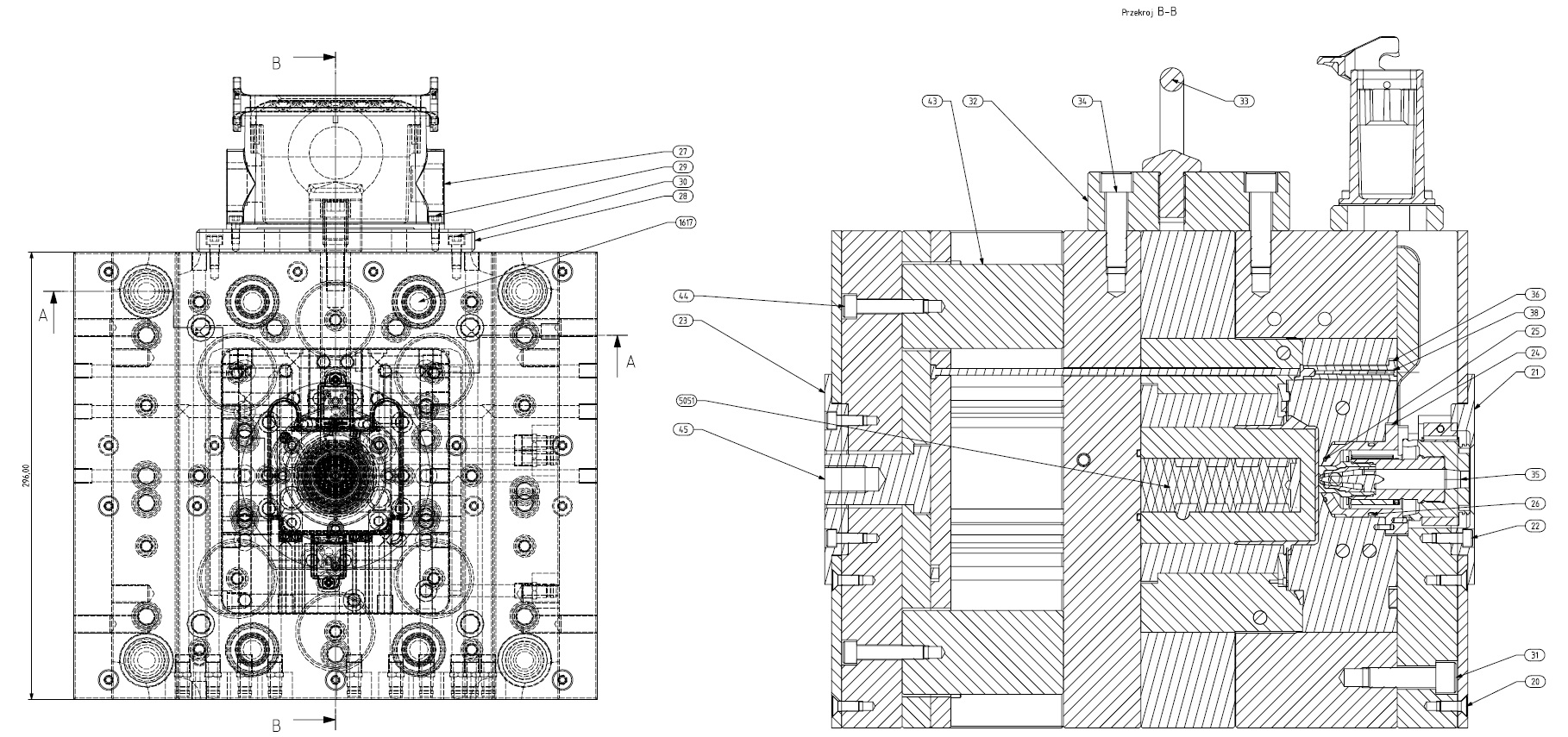

The technological process begins with the creation of the design of the structure. A refined design, taking into account the parameters of highest functionality and optimal efficiency, leads to a reduction in the cost of the manufactured parts. The result of this first stage is a data file with a construction drawing that is used as a binding working basis for the mold making.

In the second stage – the machining process – we use the most modern “state-of-the-art” machine tools with which panels with a maximum size of 496 x 696 mm can be machined. The transmission of geometry data – created on the basis of CAD programs – to the machine tools takes place directly electronically.

Molds produced by KLGS will meet your requirements: they are precise, robust and equipped with the most modern components – including HEITEC hot runner systems and HEB power hydraulics.